What fabric type to choose for your embroidery digitizing order

Choose the correct fabric type for the best results

Understanding the fabric type you will be working with helps us tailor the digitizing process to ensure the best possible results for your embroidery project.

When you are placing your order, you are presented with several options. Factors like sink, stretch, and thickness of the fabric significantly influence how we approach the design. For instance, the density and underlay we use for Polar Fleece are vastly different from what we use for Nylon fabric.

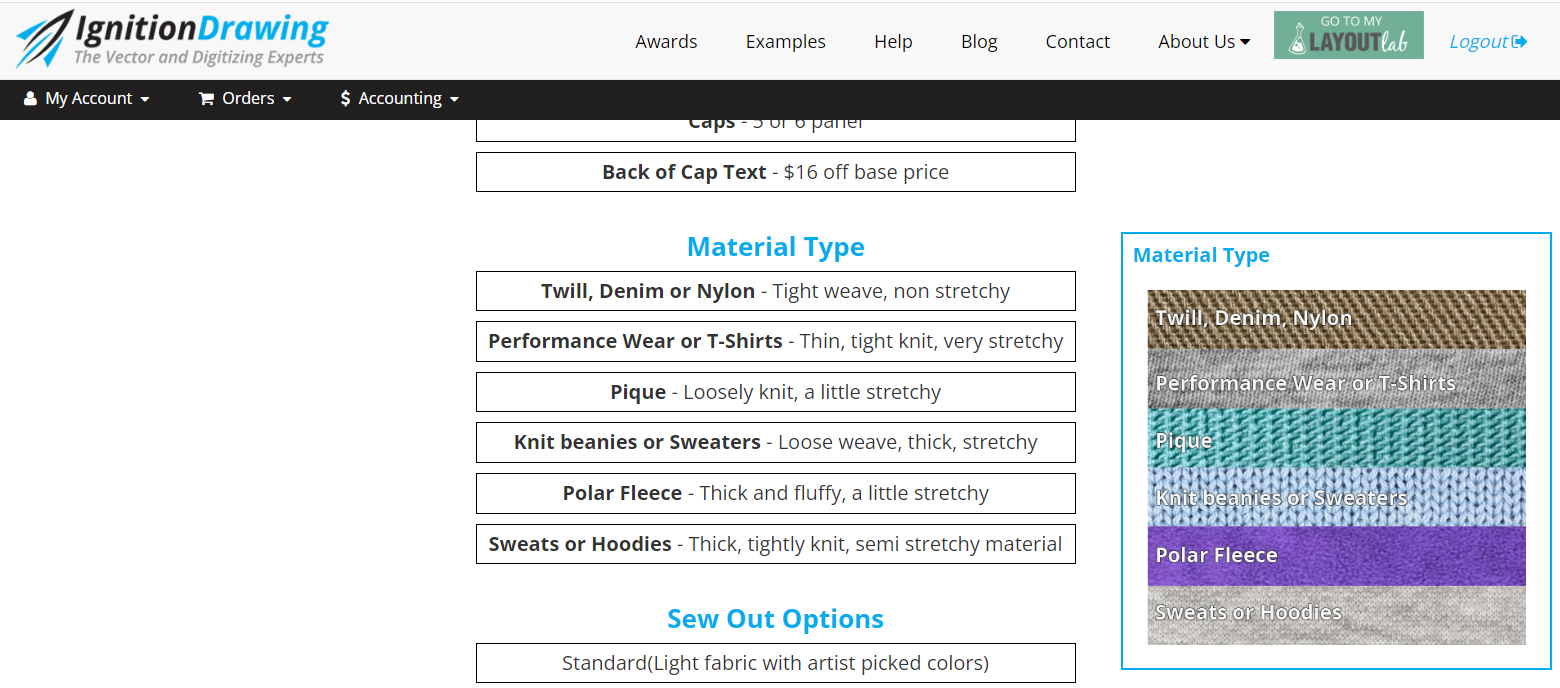

Here are the categories you will choose from as you place your order:

Twill, Denim, or Nylon

If your fabric has a fine weave, a flat surface, and is possibly stiff, it likely falls under Twill, Denim, or Nylon. These materials are common in jackets, vests, aprons, and bags. Most hats, from trucker caps to dad caps, also fall into this category.

Common Items: Satin jackets, canvas work jackets, dress shirts, aprons, jean jackets, most caps, quilted jackets, or tote bags

Performance Wear or T-Shirts

Performance wear includes most polos, T-shirts, and athletic apparel, which can be made from 100% cotton or polyester blends. The key feature of these fabrics is their elasticity, which can vary from one-way to four-way stretch. This stretchiness requires a different digitizing approach compared to twill. Some hats, like golf caps, are also made from stretchy, moisture-wicking fabrics. However, we generally don't recommend embroidering on hats made from performance wear due to potential issues like puckering and registration problems.

Common Items: Tees, polos, moisture-wicking garments or athletic wear

Pique

Pique, specifically knit pique, is a durable fabric characterized by a cross-tuck knit construction. It is thicker and stiffer than woven cotton, resists creasing, and maintains its shape well. The honeycomb-like texture of pique fabrics requires specific adjustments in our digitizing process. Pique is most commonly used in 100% cotton polos. If your garment mentions "Micro Pique," please select “Performance Wear” instead.

Common Items: Polos or golf wear

Knit Beanies or Sweaters

Knit beanies and sweaters are made from thick, yarn-like threads, creating a ribbed or textured fabric. These fabrics require more density and different underlay techniques. For designs with small lettering, we may recommend using a knockdown stitch.

Common Items: Sweaters, ski caps or beanies

Polar Fleece

Polar fleece has a thick, fuzzy surface on both the exterior and interior of the fabric. Without proper digitizing, fleece can cause embroidery to sink in, look weak, or even hide the embroidery.

Common Items: Jackets, vests or liners

Sweats or Hoodies

Also known as Jersey Knit Fleece, this fabric is commonly used for sweats and hoodies. It resembles T-shirt fabric but is heavier and has a soft, fleecy interior. The most common color is ash.

Common Items: Sweatshirts, sweatpants, hoodies or athletic wear

Still Have Questions?

If you're unsure about which fabric type to choose, don't hesitate to reach out to our team. They'd be more than happy to assist you in selecting the right fabric type to ensure the best quality of digitizing for your embroidery project. Contact us today at digitizing@IgnitionDrawing.com.